World Leading Manufacturer of Inter-connects and Materials Testing recognised by Leading Semiconductor Manufacturers globally.

Enhanced Research and Development enabling new testing methods and automatic grading of Inter-connect failures.

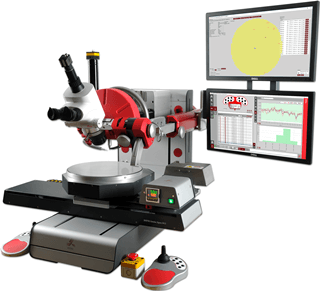

Condor Sigma Series bond testers

Performance and flexibility

The Condor Sigma is the most advanced bond tester on the market, combining the unique strengths of the Condor series with the latest technologies and innovations. Whether you need a dedicated or multipurpose bond tester, the Condor Sigma is the best choice featuring unparalleled 0.075% accuracy, the best ergonomics, highest throughput, maximum flexibility and the lowest cost of ownership.

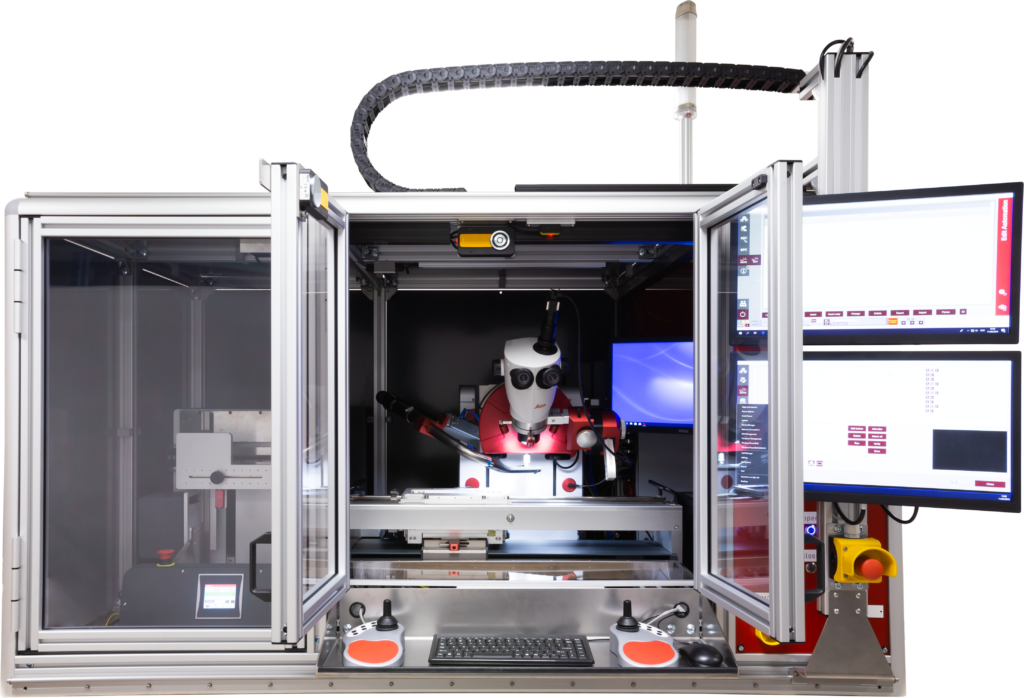

Condor Sigma MAG

Magazine handler for automated lead frame testing

Eliminate human error and reduce production cost

XYZTEC is offering the largest improvement in lead frame testing in years. By combining our state of the art Condor Sigma with an independent lead frame loader/un-loader, we can now offer our customers a hands-off bond test solution.

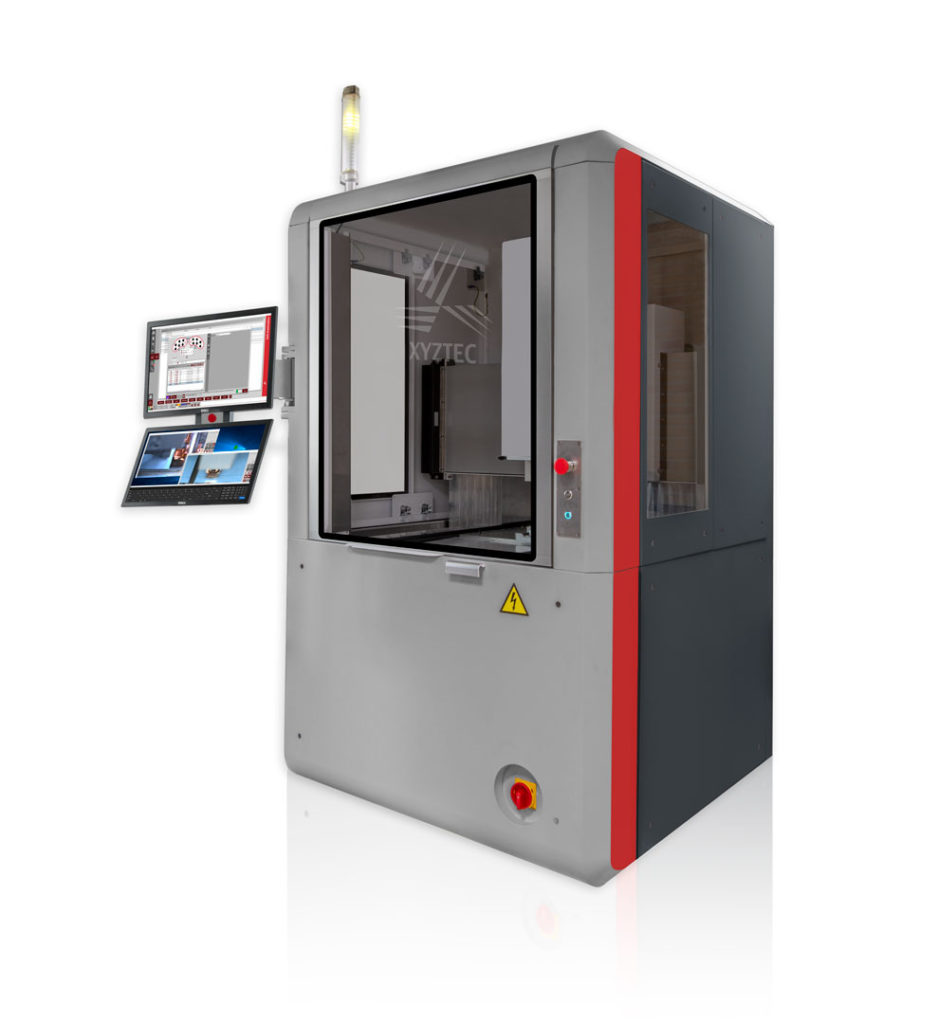

Sigma HF/L/XL

Higher force, higher speed, larger working area

A new era has begun in bond testing with our new test systems capable of applying accurate shear, pull and push forces for automotive battery applications and applications requiring a larger working area or higher forces up to 1000 kgf.

Setting new standards

XYZTEC makes it possible to test higher forces and large test volumes with higher speed up to 500 mm/s with the new Sigma L, XL and HF. A range of tooling ensures precise load application to the test point. Quick release sample clamping options ensure accurate testing together with flexible rapid load and unloading of multiple (customized) workholders.

Easy to use

This bond tester is fitted with full safety guarding that allows production line flexibility and ease of use. Access points are designed to protect the operator and provide ergonomic access for easy sample loading.

Condor Sigma W12

Ideal solution for 300mm (12 inch) wafer testing

- Precision shear testing and Cold Bump Pull (CBP)

- Big bump removal to prepare for wafer probing

- Bump sizes down to 20µm

- Available with or without wafer handler (EFEM)

- XY mapping coordinates key in function

- Grading run functionality

- Up to 4 USB Tweezers in 1 RMU

- Easy positioning, alignment

- High resolution cameras with high and low magnifications

- Fastest throughput of wafer bump testing in the world

- 500mm X-stage and 370mm Y-stage, throat depth 400mm

- Integrated report editor and flexible data export

- Reach 100% of the 300mm wafer without repositioning the wafer on the chuck

- Blower and vacuum tool cleaning unit

- Wafer chuck with safety interlocks and 360 degree rotation

- Wafer carrier mechanically locked when vacuum is turned on

- Complies with JEDEC JESD22-B117A, JEDEC JESD22-B115, JEITA EIAJ ET-7407 and IPC-9708 standards

- Also suitable for 200mm (8 inch) and other wafer sizes

- 24 bit ADC resolution, 10kHz sampling frequency

- Compatible with Revolving Measurement Unit (RMU) and single heads

- SECS/GEM protocol

- Wafer pusher to test warped wafers

- Unparallelled 0.075% accuracy